New Artificial 'Foam' Heart Pumps Fluid, Stretches Its Own Length By 300%

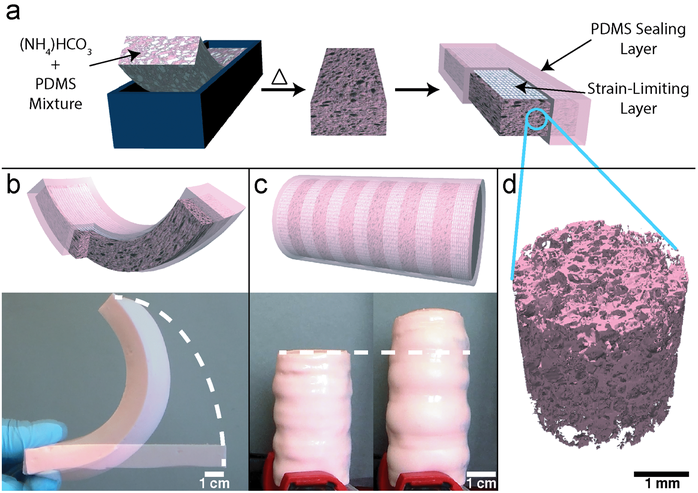

Researchers at Cornell University have designed a new type of stretchable “foam” material that can be used in a lot of different applications — and possibly even to create new artificial hearts and prosthetic body parts.

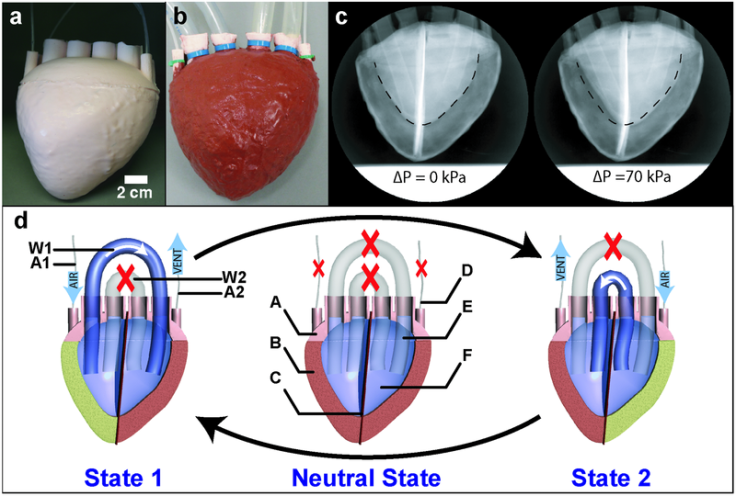

Led by Rob Shepherd, assistant professor of mechanical and aerospace engineering at Cornell, the research team created an artificial heart out of the foam, which proved to be unique due to its ability to pump fluid and contract easily.

“We used this material because it has the potential to get FDA approval,” Shepherd said in a video, “[and] because it is highly stretchable — you can stretch it by over 600 percent its initial length. We can change the pores inside of it, so we can get more or less connectivity across the material for our fluid to pass through it. It’s also very soft, so we don’t have to apply a lot of pressure to get the fluid to move through the pores.”

The polymer foam that the researchers created initially starts out as a liquid that can be poured into molds to make shapes. The pores allow for fluid to move through it easily and for the material to change shape quickly.

Initially, the researchers were experimenting with the material to use for prosthetic body parts, like hands. But they chose to design a heart with it in order to show how functional it could be.

“We decided to use a heart as an example because it’s a very complex shape, and it’s a machine that everyone’s familiar with, so by making a machine that looks like a heart that pumps like a heart, we thought it would demonstrate our material’s capability the best,” Shepherd explained in the video. “It turns out, people are actually very interested in using it as a heart replacement or even an assistant machine to a heart.”

The researchers are now working on developing a prosthetic hand with the material, though it will take some time for the polymer to be approved and tested on a federal level.

“This paper was about exploring the effect of porosity on the actuator, but now we would like to make the foam actuators faster and with higher strength, so we can apply more force,” Shepherd said in the press release. “We are also focusing on biocompatibility.”

Source: Murray B, An X, Robinson S, Meerbeek I, O’Brien K, Zhao H. Poroelastic Foams for Simple Fabrication of Complex Soft Robots. Advanced Materials. 2015.