Bioprinter Seamlessly 3D-Prints Nose Cartilage In 16 Minutes, Offers Improved Reconstructive Surgery

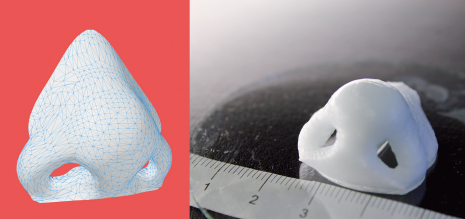

Researchers have developed a way to 3D-print nose cartilage that is able to grow with a patient’s body over time, an improved procedure to assist in reconstructive surgery on an injured nose. The method was developed by a research team from ETH Zurich’s Cartilage Engineering and Regeneration laboratory.

When a person arrives to the hospital with a smashed nose, doctors would create a digital 3D-model, then remove cartilage cells from a certain part of their body (knee, ear, or even the nose — whatever’s left of it). These cells are then combined with biopolymers, which are polymers produced by living things and are able to bond and congeal together to create bigger structures. Biopolymers are used to shape the cells when they’re placed into the nose, but the body will be able to break them down, essentially merging the transplant into the body quite seamlessly.

Ultimately, the cartilage transplant would be the same as the original cartilage. “We hope that in the future our technology could be used to overcome the need for cartilage donor tissue,” Matti Kesti, an author of the study, told Engadget. “The bioprinted cartilage piece could be printed based on the patient defect and need so that the personalized shape and size is regained.”

The authors argue that this procedure would ultimately be an improved version of the current way doctors handle cartilage transplants. Today, doctors take cartilage cells from a patient with a knee injury, for example, then cultivate them on hydrogel bands and sew them into the injured part of the knee. But this approach, known as two-dimensional cell growth, isn’t ideal, because it “lacks key spatial information for the future functioning of the patient’s joint,” the press release states. “The cells therefore form scar-like tissue instead of cartilage mass.”

3D-printing cartilage, on the other hand, would allow the cells to seamlessly grow together and retain their original function and features. The printer deposits layers of the biopolymers with ultimate precision and only takes 16 minutes.

But the researchers have some way to go before they can bring this procedure to a clinical setting; first, they have to test it out in large animals — these studies may occur this year.

“While there’s a great deal of hype around bioprinting at the moment, our research is a long way from offering things that are already being promised today,” Marcy Zenobi-Wong, a professor and the head of Kesti’s research group, said in the press release. “Our expertise is in cartilage, probably the easiest bodily tissue for bioprinting, but even today we know that this is anything but easy to print.”