Vaccine Plant Safety Checks: the FDA Has Its Hands Full

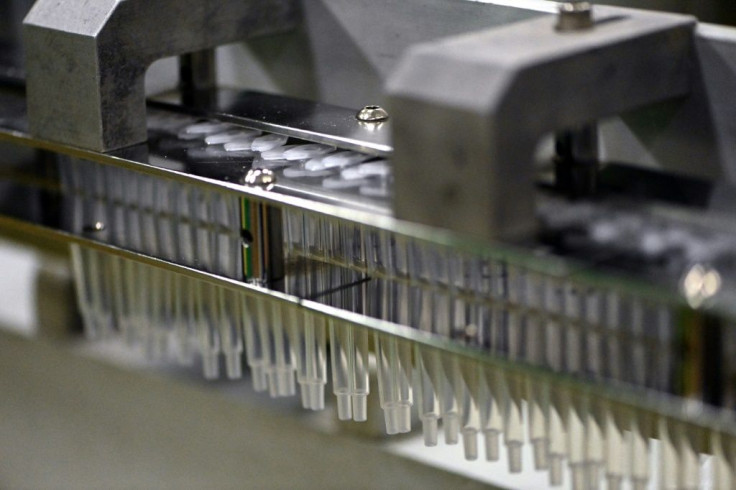

For most people across the globe, the wait for Covid-19 vaccination is approaching a finish line. But vaccine development, including tests for safety and efficacy, is only part of the story. The vaccine still needs to be produced and shipped out. A question remains: what kind of safety checks happen at the plants manufacturing the vaccines?

The process

The short, theoretical answer is yes, inspections have occurred, or will occur. The longer, realistic answer, is more nuanced. Recent reporting suggests that the FDA, regarding inspections, is stretched thin.

In response, the agency has reported that it is looking to other methods to ensure drug safety, like more inspections of drugs arriving in the US from other countries. It announced in November that it is drawing up guidance for virtual inspections. Its overseas peers, the European Medicines Agency (EMA) and the UK Medicines and Healthcare Products Regulatory Agency (MHRA), have already turned in this direction.

Generally speaking, and according to the FDA’s Compliance Program Guidance Manual, the agency conducts inspections of all plants every two years. The inspections can happen more frequently if the FDA deems them necessary, usually when there’s a new license or approval application or if there has been a significant change to the product or facility. It normally sends one or two inspectors to a plant.

In March 2020, the FDA announced that it would be suspending all facility inspections, both at home and overseas. The agency’s Guidance For Industry indicates that FDA inspectors will review: existing inspection reports; information from other regulatory agencies, such as the MHRA and EMA, and; documentation from the parties involved. “Mission-critical” inspections will still be carried out, as will high-priority ones in areas deemed safe.

Surveillance inspections are part of the prioritized category, while the “mission-critical” label is reserved for significant breakthroughs, advanced therapies, and for products that treat or prevent a serious disease that has no other treatment available.

The challenges

The FDA has had difficulty keeping up with foreign facility inspections. A US Government Accountability Office showed declines in the number of inspections, with domestic inspections dropping 13% and foreign ones by 10% between fiscal years 2016 and 2018. Declines in the number of inspectors didn’t help; replacing and training new inspectors can take at least 1.5 years.

The GAO said the FDA’s efforts to find other means for inspections would not make up for the lack of foreign inspections. “[This reduction] removes a critical source of information about the quality of drugs manufactured for the U.S. market,” the report said.

In October 2019, Janet Woodcock, MD, then-director of the Center for Drug Evaluation and Research (CDER) at the FDA told a House subcommittee that more than 70% of active ingredients for medications sold in the US are produced overseas. She said the drop in foreign inspections was due to lack of staffing and the 2019 congressional mandate for domestic inspections.

According to the report, the agency decides what facility to inspect based on risk.

Despite staffing issues, Dr. Woodcock maintained that the FDA is following its policies and carries out proper inspections and follow-up. In the end, she noted, “90 percent or more of the final outcomes of inspections were acceptable ... in all countries or regions except India.”

This information lines up with the official data, which show the vast majority of the investigations end with the “NAI” (No Action Indicated) label. That means that either no problems were found or that the FDA feels that any issues were not significant enough to justify taking action. VAI, the next step up, means that potential problems were found but that corrective action is voluntary.

What does this mean for the vaccines?

The agency does not require on-site inspections for products that have received emergency use authorization, like the two Covid-19 vaccines recently approved. Inspections for vaccine manufacturers include the facility’s previous history and records, to decide whether an on-site inspection is needed.

Vaccine developers with emergency use authorization must provide the agency a detailed report of their production process. The developers also must prove it has a quality control group.

The FDA, according to a Vanity Fair article, said two investigations of Covid-19 manufacturers have already taken place. It did not specify whether any in-person visits had occurred or whether reports on the investigations will be made available to the public. The Pfizer and Moderna vaccination production is taking place in many countries.

The December 2 Vanity Fair article, which said the inspections group was understaffed -- 14 members -- said that the inspections at the Covid-19 vaccine plants are more limited and are being documented with internal memos instead of full reports.

And these documents will not be released to the public, said Arie Menachem, a former member of a specially trained facilities inspection group, in the Vanity Fair article. The group’s responsibilities include inspecting vaccine production plants.

According to Mr. Menachen, he alone conducted an inspection in October 2018 at one facility in North Carolina; for prior inspections, the FDA sent two inspectors. By his estimation, it stretched the length of 13 football fields combined. According to the article, FDA procedure for staffing any inspection prompted by a whistleblower event, as this one was, called for two inspectors.

Vanity Fair also reported that 77% of this group’s inspections found compliance issues between 2010 and 2014, with 3% of all inspections generating an official warning. Between 2015 and 2019, the compliance issues’ percentage jumped to 86%. The article reported that the FDA issued no warning letters.

The take home

Covid-19 has caused many changes, but the FDA still has clear and defined policies for ensuring manufacturing is done safely. When taken alongside Menachen’s stories, however, there may be room for concern. The FDA did not respond to our request for comment on whether facility inspections were performed for the new Covid-19 vaccines. The official data says that most facilities come up clean, but firsthand reports don’t look quite so rosy.

Sean Marsala is a health writer based in Philadelphia, Pa. Passionate about technology, he can usually be found reading, browsing the internet and exploring virtual worlds.