Relativity Space Will 3D Print Mars-Bound Rockets For NASA

Relativity Space, a three year-old aerospace startup based in Los Angeles, California, has begun a project that will eventually see it 3D print rockets that might one day take astronauts on the 225 million kilometer-long trek to Mars.

It said it will lease space at NASA’s Stennis Space Center rocket-testing facility in Mississippi to initially 3D print low-cost rockets that will launch small-payload satellites into low Earth orbit or LEO. Relativity’s Stennis facility will eventually employ 200 engineers, which is double the company’s current workforce of 90. Mississippi has offered a significant incentive package for Relativity Space to do business in the state.

CEO Tim Ellis said the company’s ultimate mission is to 3D print rockets that will travel to Mars. Ellis said 3D printing launch vehicles is a prerequisite for space colonization.

Ellis pointed out Relativity Space must first perfect a system where machine-learning robots can manufacture and assemble its flagship “Terran 1” rocket in space without help from humans.

“We’re reducing the human labor component significantly,” said Ellis

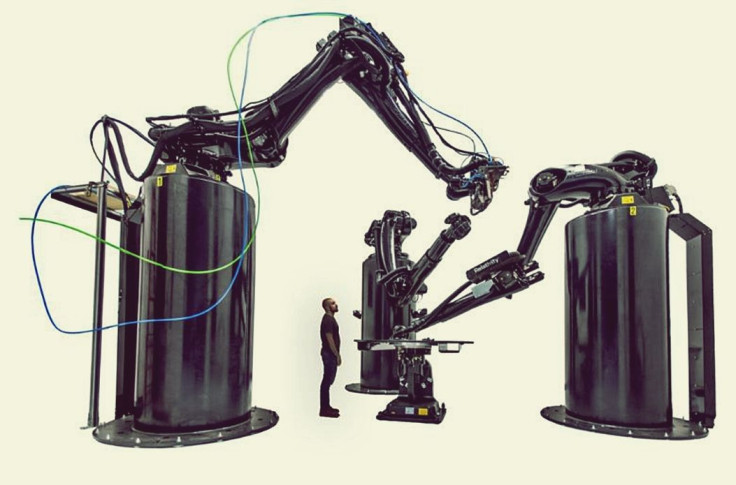

Making this rocket will be the job of Relativity’s two-storey tall 3D printer arms named Stargate. This machine will enable the production of an entire rocket in fewer than 60 days, said Ellis. Stargate is the backbone to the company’s vertically integrated factory.

The mammoth Stargate 3D printer with its 18 foot-tall robotic arms is equipped with lasers that melt metal wire. These robotic arms can stream eight inches of metal onto a large turntable in just a few seconds.

Controlled by custom software, the robotic arms are capable of producing an entire rocket booster in one piece. This advantage allows Relativity Space to reduce the part count of a typical rocket from 100,000 to just 1,000, which greatly saves on time, labor and money.

Using Stargate also allows Relativity to print rockets capable of lofting large payloads up to the size of a small car. This is six times the capability of its competitors, claims Relativity.

Relativity Space intends to launch nearly two dozen rockets a year over the next five years to prove the company’s 3D production method is both feasible and inexpensive compared to traditional production methods.

Maiden launch for Terran 1 is expected by 2020. A mission using Terran 1 will cost $10 million per flight. This launch vehicle can loft 2,755 pounds (1,250 KG) to LEO. Terran 1 will stand 90 feet-tall and will measure 7 feet-wide.

In February 2018, Relativity released a video showing the test firing of its entirely 3D printed rocket engine named Aeon 1. The engine went from ignition to full thrust in milliseconds during the test at Stennis.

Relativity claims Aeon 1 takes far less time to build than a traditional rocket because it is 3D printed. It said it took one month to 3D print the engine instead of the usual six months using traditional methods of assembly and fabrication.