Researchers At Carnegie Mellon University Used Inexpensive 3D Printers To Rebuild Damaged Hearts

The marriage of 3D printing and medicine has been a fruitful and awe-inspiring one. We’ve seen it save a baby’s life before the baby was even born; it’s given a cancer patient a brand new rib cage; and it’s even helped to create a nose that grows on the patient over time. As we slowly make our way to becoming more indestructible human beings, it was only a matter of time before we discovered a way to create 3D-printed organs. Since our hearts are the most important — albeit fragile — part of our anatomy, researchers from Carnegie Mellon University set out to use 3D printing to heal damaged hearts.

People with failing hearts have very few options besides getting a transplant, because when heart tissue is damaged, it’s unable to heal itself — unlike other parts of the body. The work done at Carnegie Mellon University, published in the journal Science Advances, shows that one day, 3D printing could usher in a time when damaged hearts can be healed instead of transplanted.

"We've been able to take MRI images of coronary arteries and 3D images of embryonic hearts, and 3D bioprint them with unprecedented resolution and quality out of very soft materials like collagens, alginates, and fibrins," said Adam Feinberg, an associate professor of materials science and engineering and biomedical engineering at Carnegie Mellon University, in a press release.

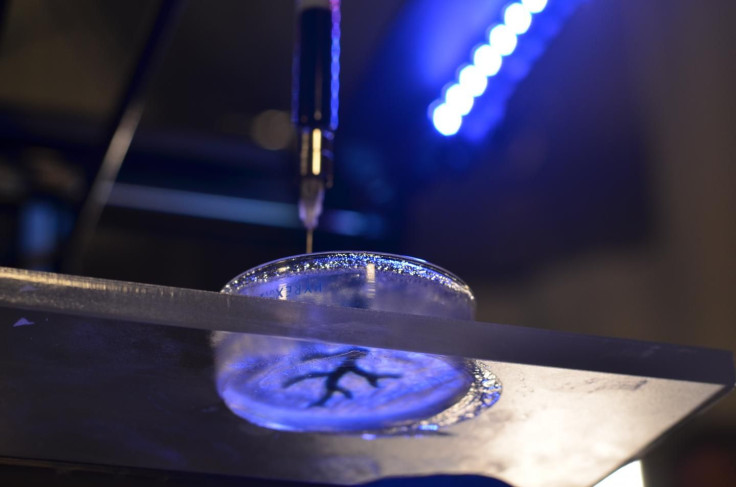

Traditional 3D printing utilizes hard materials — hence the aforementioned rib cage — which are dropped layer-by-layer on top of each other until the piece is complete. The researchers couldn’t do this with their bio-materials, which have the consistency of Jell-O, so they devised a solution. "The challenge with soft materials is that they collapse under their own weight when 3D printed in air," Feinberg explained. "So we developed a method of printing these soft materials inside a support bath material. Essentially, we print one gel inside of another gel, which allows us to accurately position the soft material as it's being printed, layer-by-layer."

The researchers used an advanced technique called Freeform Reversible Embedding of Suspended Hydrogels (FRESH) to free the 3D-printed parts, such as an artery, from the support gel. By heating the gel to body temperature, they were able to remove the parts without damaging the molecules or living cells inside. The researchers will begin working toward incorporating real heart cells into the tissue structures they print. They hope to eventually develop contractile muscles, which help the heart move and pump blood.

As expensive as 3D bioprinters may be (upward of $10,000), Fennigan stated that the team was able to create its 3D biomaterials with consumer-level printers, which only cost about $1,000, and open-source hardware and software. "Not only is the cost low, but by using open-source software, we have access to fine-tune the print parameters, optimize what we're doing and maximize the quality of what we're printing," Feinberg said. "It has really enabled us to accelerate development of new materials and innovate in this space. And we are also contributing back by releasing our 3D printer designs under an open-source license."

Source: Fennigan A, et al. Science Advances. 2015.

Published by Medicaldaily.com